Your Trusted Lifting Solutions Partner. Magnum Lifters and Tackles delivers high-quality lifting equipment, expert advice, and reliable solutions, serving commercial and industrial applications. As authorized dealers for renowned brands - USHA MARTIN WIRE ROPES, Mega Link Chains, Universe Hoist, and INKKA Web Slings - we empower safe and efficient lifting operations across various workplaces.

A Pulling and Lifting Machine is a type of equipment used to lift, pull, or move heavy loads, objects, or materials. These machines are designed to provide mechanical advantage, making it easier to handle and maneuver heavy weights.

The "Universe" gearless hand operated pulling and lifting machines are used for rectilinear pulling of steel wire ropes by the gripping and releasing actions of two sets of jaws alternately. Each set consists of a pair of smooth jaws of suitable length which grip the wire rope firmly by closing top and bottom without causing damage to the rope. These jaws work on the self-clamping principle, that is they are locked by the pulling force of the wire rope itself. The jaws are enclosed in a casing and are connected by rods to forward (or up) and reverse (or down) mechanism which is operated by a telescopic handle.

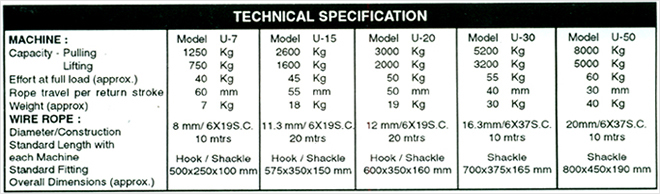

Galvanised steel core wire ropes of 6X19 construction up to 12mm diameter and 6X36 or 6X37 construction above 12mm diameter shall be used. A galvanised wire rope with fibre steel mixed core may also be used if agreed to between the manufacturer and the purchaser.

The enquiry and order should give the following details: